Reefer or refrigerated

Manufacturing | Sale | Delivery

Why use reefer or refrigerated containers?

Refrigerated or reefer containers can be found in different sizes (also different of the standard 20´ and 40’) and and its main feature is the creation of an environment with controlled temperature by having thermo-acoustic insulation that has a refrigeration unit for temperature control.

All new reefer or refrigerated containers have the same refrigeration technology, guaranteeing lower costs and energy consumption expenses. To maintain this controlled environment, they must be connected to a power source during the transport journey, ensuring never breaking the cold chain.

Key piece for the transport of perishable products

Sea containers are more suitable for the international transport of differents kind of goods, however, reefer containers are considered workhorses of international trade for transporting perishable products such as food or those that require a certain temperature.

Many companies prefer to use standard reefer containers for cold storage, especially when it comes to long-term storage with limited access required.

Technical Information and Characteristics of Reefer or Refrigerated Containers?

Main estructure

Lining of the 40 ‘container in a 100mm panel.

The interior enclosure it´s made of 100mm panel, walls, ceiling and floor, overlapping floor of 21mm phenolic board.

Access to the cold room through a pivoting door of 1,200 x 2,100.

New Reefer with cold machine

Stainless steel interior with aluminum floor - Refrigerated door

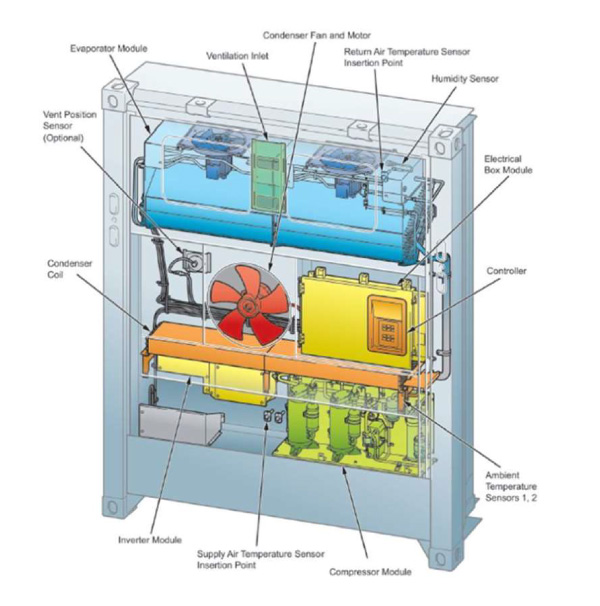

Motor condenser with horizontal discharge axial fan for medium temperature cooling, INTARCON brand, model MDH-NY- 5271 manufactured in pre – lacquered galvanized steel body and chassis.

Danfoss Maneurop hermetic reciprocating 13 HP compressor mounted on shock absorbers, with discharge silencer and internal clixon. Battery copper tubes and aluminum fins. Refrigerating circuit made of annealed copper tube equipped with high and low pressure switches, safety valves , liquid container, filter and sight glass.

Proportional control of condensation pressure by varying the fan speed. Power and maneuvering electrical panel, with compressor and motor fan magnetothermic protection.

- Equipped with electromechanical suction pressure control (low pressure stop).

- R134a refrigerant.

- Power supply 400V 3N ~ 50Hz.

- Pot. Refrigeration (T evap .: -10 ° C / T outside: 32 ° C): 11770 W.

- Pot. Nominal absorbed: 6390 W.

- Condensation flow: 4300 m3 / h.

- Refrigeration connections (liquid-gas): 1/2 '' - 1 3/8 ''.

- Sound pressure level 10m: 48 db (A).

- Dimensions: 1290x755x656 mm.

- Weight: 171 kg.

- Equipped with electronic regulation with remote control digital control. MKC-NY-4435 evaporator unit.

- OPT. DE.9.0.

Evaporator unit

Cubic type evaporator unit for medium temperature refrigeration, INTARCON brand, model MKC-NY-4435. Designed to work with r134a.

Built with a pre-lacquered galvanized steel frame and body. High efficiency coil made of copper tubes and aluminum fins. Stainless steel folding condensate tray.

High flow axial motor fans. Factory preset adjustable thermostatic expansion valve and solenoid valve. Refrigeration connections to be welded, with integrated suction line siphon.

- Power supply 230V ~ 50Hz.

- Defrost by air.

- Cooling capacity (T chamber: 10 ° C, 85% RH / DT1 = 10 K): 22100 W.

- Cooling capacity (T chamber: 0 ° C, 85% RH / DT1 = 8 K): 14600 W.

- Fans: 4 x Ø350 mm.

- Power absorbed by the fans: 645 W.

- Air flow: 8300 m3 / h.

- Range: 15 m.

- Refrigeration connections: 5/8 '' - 1 5/8 ''.

- Fin pitch: 6mm.

Our refrigerated containers have freezing capacity and are ideal for storing products that need low temperatures (down to -30 ° C) such as ice cream, meat and fish. Preserving in this way the cold chain and the prolongation of the life cycle of the products.

This system is used in perishable commodities, such as vegetables or other goods that need temperature variations during transport and storage.

In this function, fruits are generally transported, which require maintaining a specific and precise temperature during the journey. Correct refrigeration is essential to prevent the appearance of possible parasites such as flies, ensuring that they are kept in optimal conditions and preserving their original presentation with freshness and quality.

- Rear doors

- Aligned grids

- The loading of the pallets is insured

- Space for airflow on the sides

- Cover allows vertical airflow

- Air space above the boxes

- Cooling unit

The boxes do not leave the pallets

Cold equipment

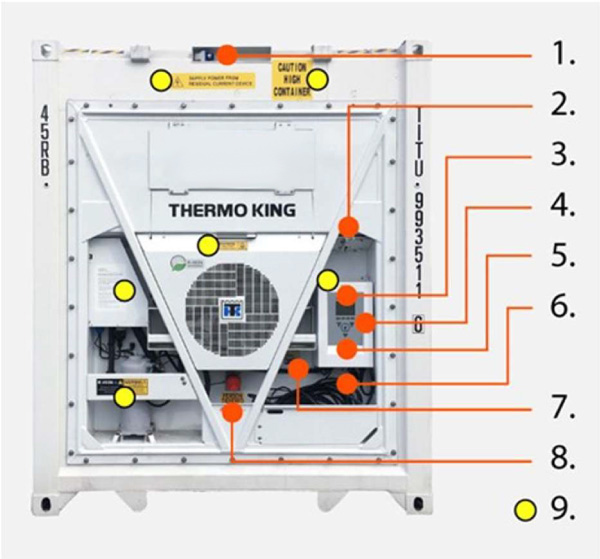

- 1. Electrical connection

- 2. Outside air exchanger

- 3. Instructions for use

- 4. Temperature information panel

- 5. ON / OFF

- 6. Control panel

- 7. CE certificate

- 8. Trapped man alarm

- 9. Cable de conexión 380/440V y 220/240V

- 10. Safety notices

Freezing Equipment

- 1. Electrical connection

- 2. Outside air exchanger

- 3. Temperature information panel

- 4. ON/OFF

- 5. Control panel

- 6. CE certificate

- 7. Trapped man alarm

- 8. Connection cable 380 / 440V and 220 / 240V

- 9 .Safety notices

Custom containers:

Our team of consultants and engineers are trained to deliver a customize product to you, if the standard-size containers not fit your needs.

Quick contact

If you need further information or any kind of assistance contact us through this form and our specialists will reply in a short period of time.

To have a more detailed budget, go to the advanced budget request , this will take more time, but you will receive a more specific and appropriate response to your needs.